FURTHER DEVELOPMENT OF PRODUCTION PROCESSES

PRODUCTION-ORIENTED OPTIMIZATION

Production engineering is an area of our service spectrum that deals with the planning, development and implementation of processes for the manufacture of products. It includes all processes, tools, machines and techniques needed for the production of goods in industry as well as other sectors.

In the field of production engineering we offer know-how in the following sub-areas:

- Forming technology: In this process, workpieces are brought into a specific shape by plastic deformation. Examples of forming processes include forging, rolling, bending and deep drawing.

- Cutting technology: In this area, workpieces are brought into the desired shape by cutting, sawing, drilling or milling. The separation of materials by means of laser or water jet is also part of the separation technology.

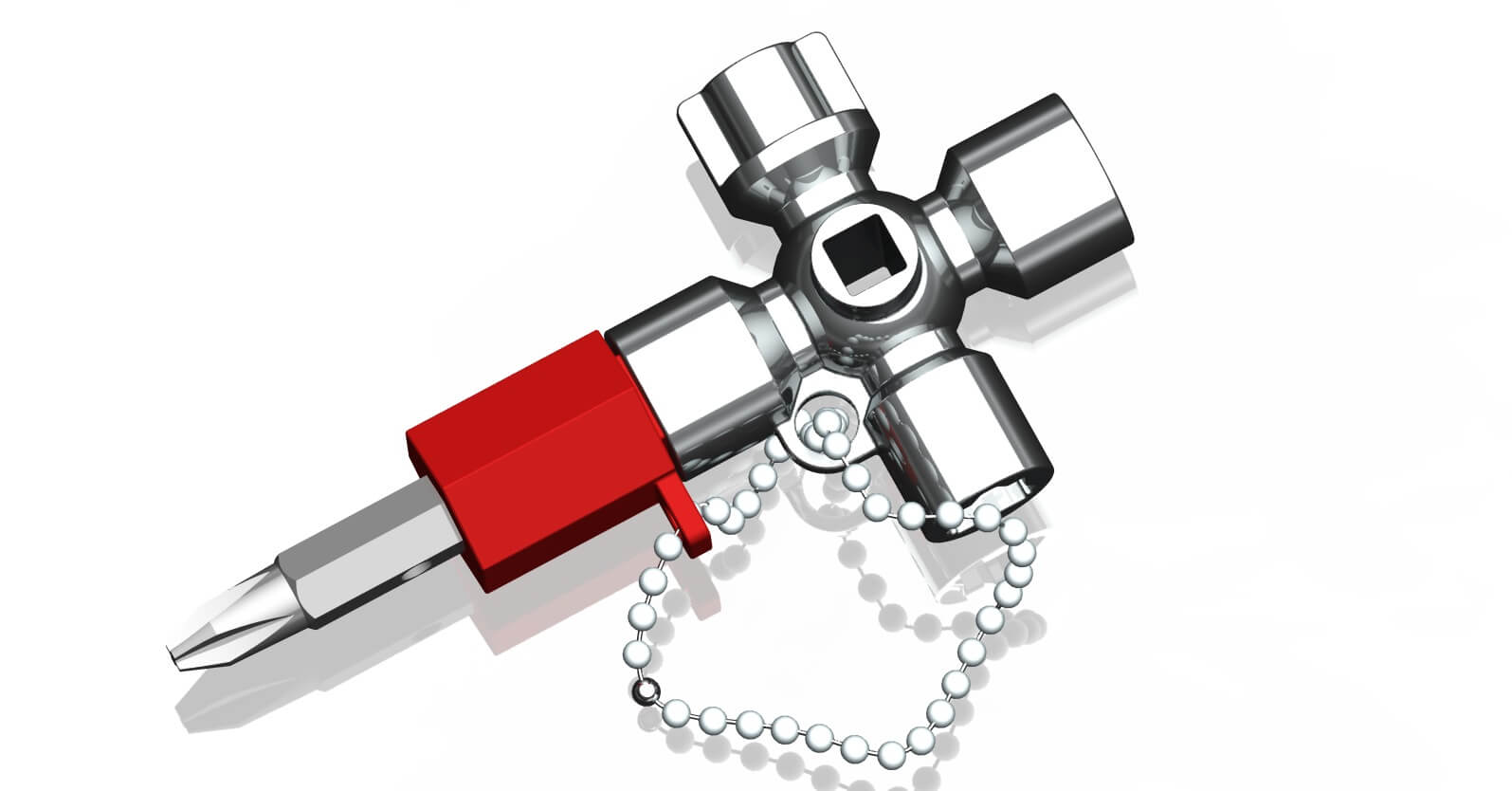

- Joining technology: In this process, several workpieces are joined to form a single component. Examples of joining processes are welding, bonding, soldering and screwing.

- Machining: This sub-sector includes the removal of material by cutting or ablation using tools such as lathes, milling machines or drilling machines.

- Additive Manufacturing: Also known as 3D printing, additive manufacturing enables the layer-by-layer production of components from various materials. This area has become much more important in recent years.

- Assembly technology: In this process, individual components are joined together to form a finished product. Assembly techniques can be manual or automated.

Manufacturing technology plays a crucial role in industry, and forms the basis for production. Through continuous development and optimization of manufacturing processes, we can increase efficiency, reduce costs and improve the quality of manufactured products.